Despite enjoying many preferential policies from the government over the past 20 years, Vietnam’s automobile market is in the beginning phase of motorization. With a population of 100 million people, Vietnam has huge potential for development in the long term.

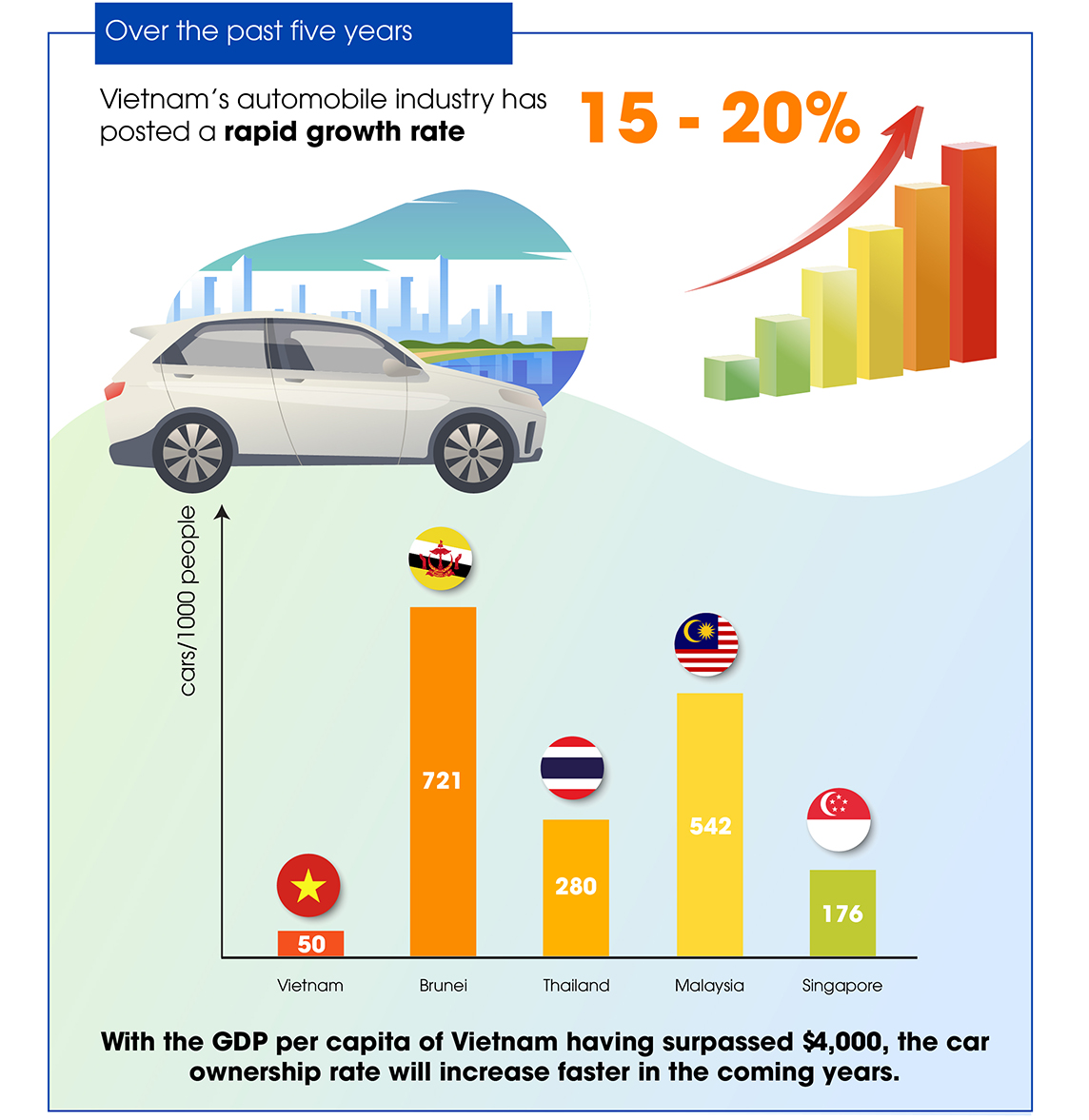

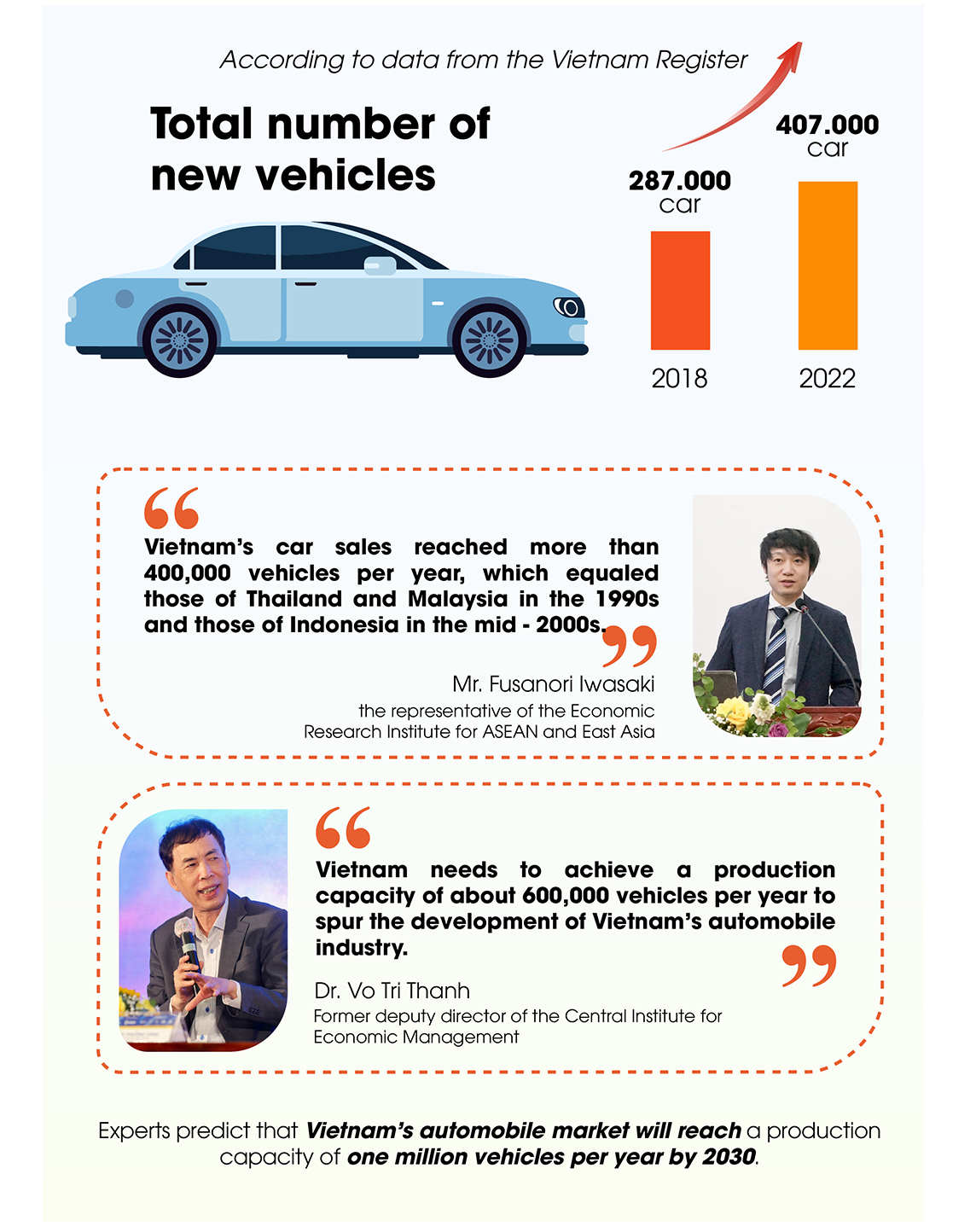

Over the past five years, Vietnam’s automobile industry has posted a rapid growth rate of 15 – 20% on average. According to statistics, Vietnam only has about 50 cars per 1,000 people, which is much lower than that of Brunei with 721 cars, Thailand with 280 cars, Malaysia with 542 cars, and Singapore with 176 cars. With the GDP per capita of Vietnam having surpassed $4,000, the car ownership rate will increase faster in the coming years.

It is the reason why, despite the severe impact of the pandemic over the past two years, many automobile manufacturing and assembly companies have made ongoing investments to scale up and keep up with the trend of economic recovery in the coming years.

At the end of 2022, Toyota Vietnam put two models into production and assembly at the factory in Vinh Phuc province instead of importing completely built unit (CBU) cars from Indonesia.

In mid – November 2022, Thanh Cong Group and Hyundai Group officially inaugurated Hyundai Thanh Cong Factory No. 2 in Gian Khau Industrial Park (Gia Vien – Ninh Binh), with a total design capacity of 100,000 vehicles per year.

The BMW Group has also announced a partnership with Thaco Auto to assemble some BMW models at the factory in Chu Lai.

Most recently, TMT Group has a plan to form a joint venture with a Chinese manufacturer to assemble small electric vehicles in Vietnam…

To achieve this milestone, it is necessary to build a sufficiently strong supporting industry (manufacturing and supplying spare parts and components), along with rapidly improving road infrastructure, developing smart cities, making efficient use of tax mechanisms, and others. However, an indispensable condition in line with the current trend is to develop factories that can minimize environmental pollution with environmentally friendly materials.

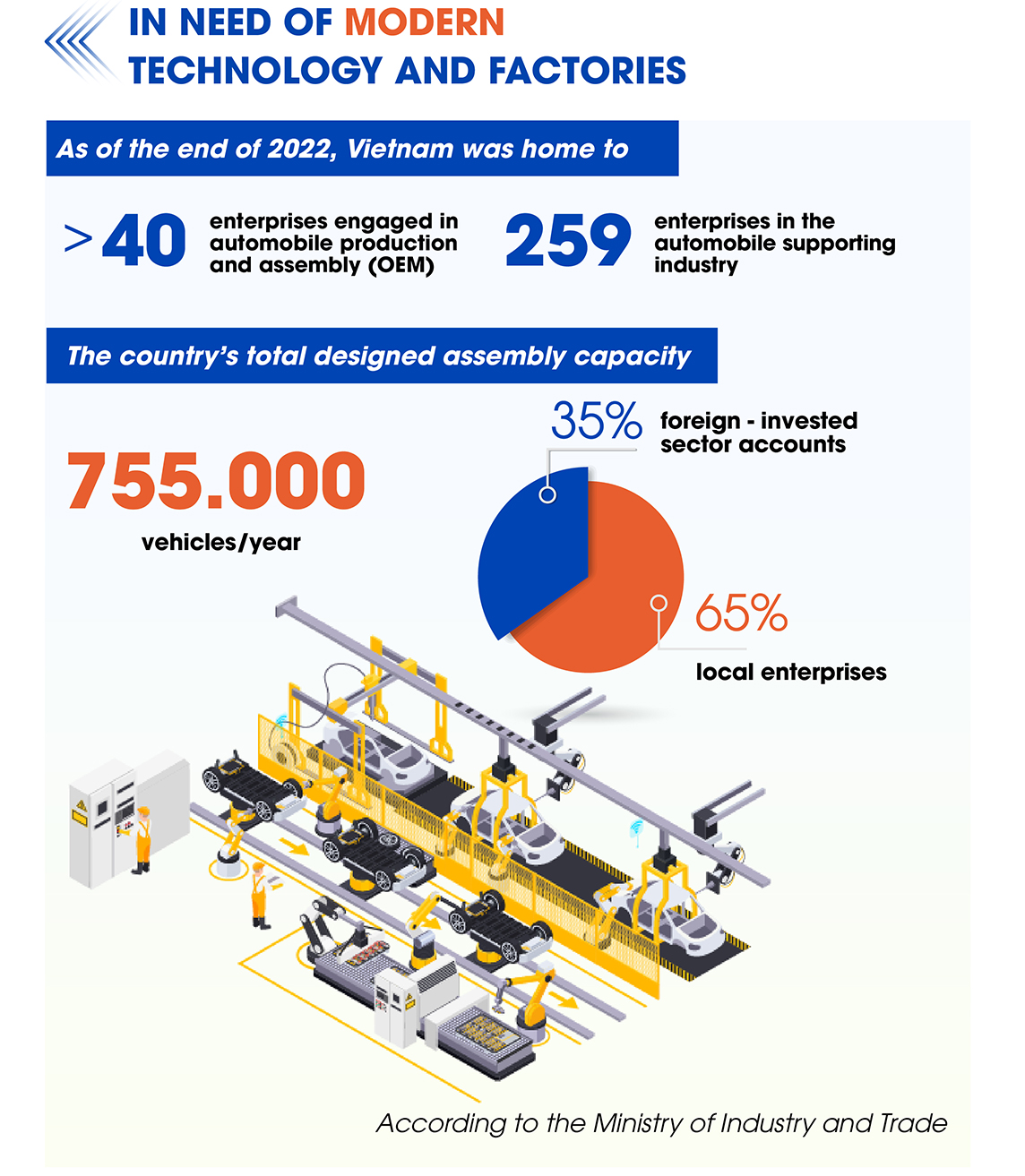

Although the industry seems “crowded” and the government aims to increase the localization rate,

The current limitation is that Vietnam’s automobile industry is mainly assembling cars, with a real production foundation yet to take shape. The production lines mainly revolve around four stages, including welding, painting, assembling, and testing. The factories and technologies are not modern, failing to meet green, environmentally friendly, and emission-reduction standards. Meanwhile, this is an inevitable trend in line with international commitments.

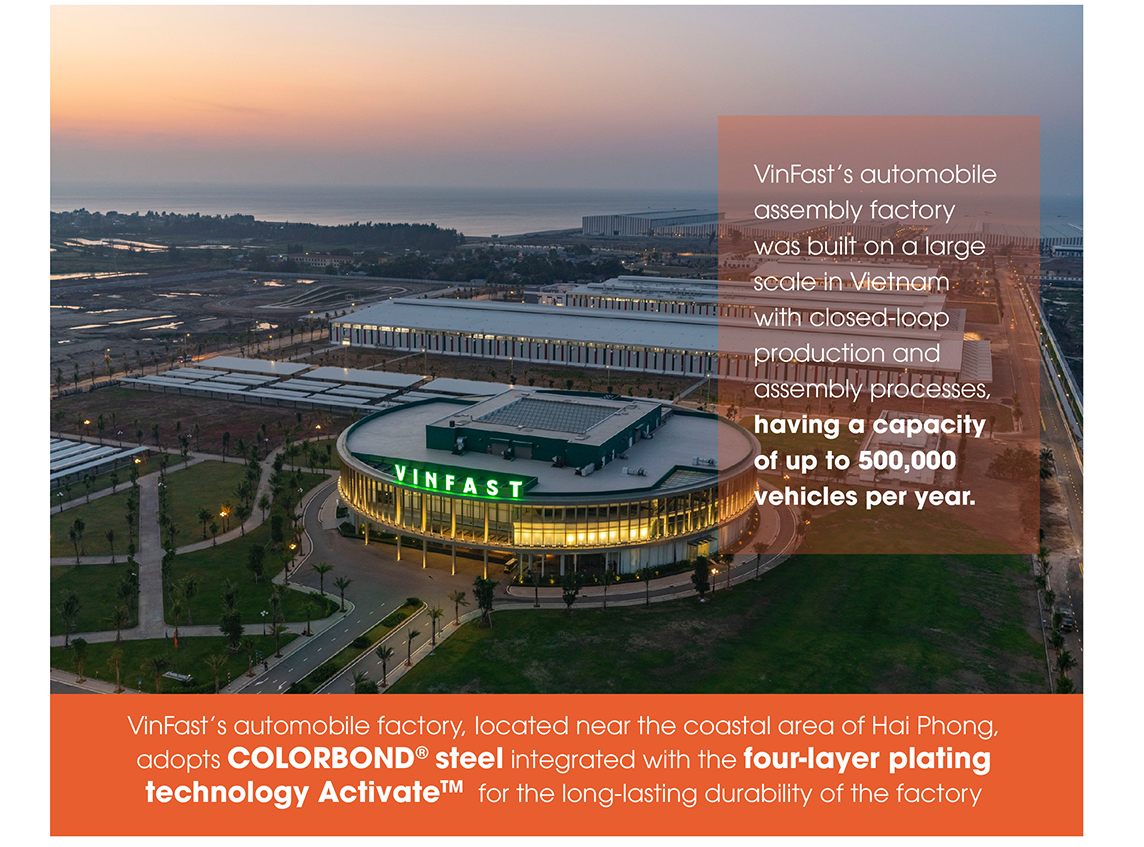

According to the representative of VinFast Manufacturing and Trading Co., Ltd., every company must fulfill all requirements for an automobile assembly factory before proceeding with construction and production. VinFast’s automobile assembly factory was built on a large scale in Vietnam with closed-loop production and assembly processes. The factory boasts six workshops, including stamping, painting, bodywork welding, engine manufacturing, assembly, and auxiliary, applying modern European technology and having a capacity of up to 500,000 vehicles per year.

According to VAMA, automobile manufacturing and assembly factories must be fully equipped to ensure industrial hygiene, labor safety, hazard reduction (noise, heat, dust), fire and explosion prevention, as well as protection of the landscape, environment, and industrial civilization. According to BlueScope, a provider of innovative steel materials, products, systems, and technologies, Vietnam’s automobile industry possesses huge potential and attractiveness. There has been a relocation wave and investment attraction as well as a race to scale up automobile production in the coming years. It is the reason why the Australia-based steel company focuses on providing modern steel technologies for buildings and factories, especially in the automobile manufacturing industry.

Since 2004, the Ministry of Industry (now the Ministry of Industry and Trade) has issued Decision No. 115/2004/QD-BCN on criteria for automobile manufacturing and assembling enterprises. It stipulates that the factories, production areas, and workshops must have adequate space for the arrangement and implementation of manufacturing, assembly, and testing, as well as other necessary areas for the operation and post-test processing. Manufacturing and assembly areas, covering workshops for painting, welding, and testing, must be arranged according to appropriate technological processes.

Truong Thanh Hoai, Director of the Department of Industry, cited the Government’s Decree No. 116/2017/ND-CP on requirements for manufacturing, assembly, import, and trade in automobile warranty and maintenance services. It stipulates that enterprises must have the legal rights to use the factory, assembly line, welding line, painting line, quality control line, and testing road, meeting the minimum requirements. It is one of the requirements for the Ministry of Industry and Trade to issue a certificate of eligibility for automobile manufacturing and assembly in Vietnam.

Comment