Composite steel and concrete structure and floor decking are globally known as an advanced solution to replace the traditional reinforced concrete and a “representative” of a sustainable construction trend.

Sustainable construction, by nature, pursues the ultimate goal of mitigating environmental footprint by utilizing materials to construct more at less, employing construction efficiency, controlling work-related accidents at the lowest level, etc., which makes it an inevitable industry trend. Taking advantage of such the latest technology as decking solution is a part and parcel of this sustainability journey.

Composite steel and concrete floor decking are a mixed structure between concrete and steel floor, in which steel floor is engineered in waveform with specialized shapes to minimize its thickness and weight. This kind of floor does not require formwork, making it thin and light thanks to the use of cast-in-place concrete, which leads to positive impacts on the building frame and foundation. Composite steel and concrete floor decking is currently an industry prevailing trend, widely applied for industrial, multi-floor, commercial, civil, and public buildings worldwide… with proven efficiency.

According to Dr. Pham Cao Hung, Senior Lecturer at The University of Sydney (Australia), composite steel and concrete structure emerges as a popular choice in worldwide buildings, especially for multi-story structures. Apart from being prominent compared to traditional reinforced concrete structures in terms of high load capacity, long-spanning, compact and aesthetic components, the prefabricated steel of composite steel and concrete structure allows an easy of construction with less time, labor cost, and construction waste and without formwork.

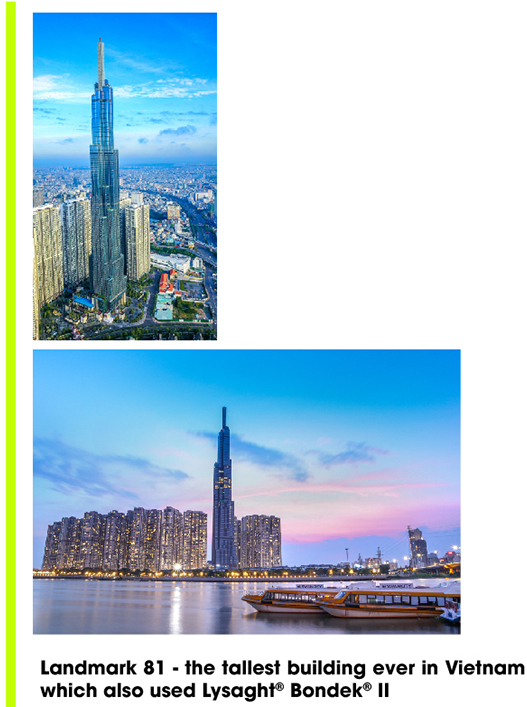

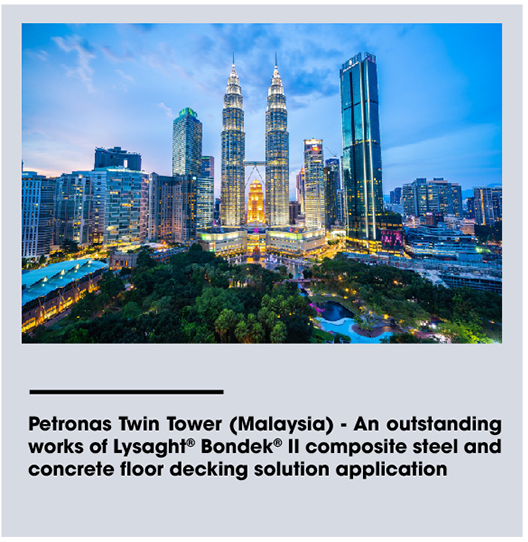

In response to the latest industry trends based on the Company’s in-depth insights of the local market, Ns BlueScope Lysaght has launched LYSAGHT® BONDEK® II since 2017 – the best-of-breed solution from Australian experts – As a viable alternative to traditional formwork and bottom reinforcement steel mesh for concrete slab system. Such solution is not only used for the iconic buildings across the globe as Marina Bay Sand (Singapore), Changi Airport (Singapore), Petronas Twin Tower (Malaysia), One Shelley Street Building (Australia), etc., and is present in notable industrial projects in Vietnam like Thaco Truong Hai factory in Quang Ngai, Long Beach Resort in Phu Quoc, Kizuna Ready Serviced Factory in Long An, Millennium in Quang Ngai and Vietnam’s pride of Landmark 81 – the tallest building ever in the country.

Upon ceaseless improvement years, NS BlueScope Lysaght Vietnam’s composite steel and concrete floor deck is known as one of the solutions that may save cost up to 15% and accelerating the construction progress by approximately 20% compared to traditional concrete, saving installation and formwork removal time, smart profile support for M&E hanging system, and maximization of safety in construction, reducing the risks of scaffolding issues.

Its aesthetic and durable finished surface is supported with the most advanced steel integrated with Activate™ technology as what is further referred to by the technical expert of NS BlueScope Lysaght Vietnam.

Dr. Hung also unveiled that many design standards and codes are currently applied for a composite structure such as AISC 360-16 in the USA or EuroCodes 4 in Europe and AZ/NZS 2327:2017 of Australia.

In Vietnam, the design under Eurocodes and Australian standards are opted in by NS Bluescope Lysaght. The design software MEGAFLOOR is also specifically written for LYSAGHT® BONDEK® II floor panel with three steps:

Decking quality is verified by the manufacturer through Australia standard tests on spanning capacity during concrete works, binding between decking and concrete as a binding assembly, and fire safety of the floor panel assembly under BS476 standard. “LYSAGHT® BONDEK® II decking assembly is characterized by minimum REI of 60 minutes and maximum REI of 240 minutes (under BS476 standard). Meanwhile, the maximum REI of 60 minutes is just required by QC 06 – 2020 for grade I work decking,” further shared by the firm’s technical expert.

Recently, the solution has been introduced to the construction business community in a webinar in mid of August by NS BlueScope Lysaght Vietnam. “Hopefully, the industry players may successfully access to the world’s advanced construction trend, apply to the practice, then gradually improving the general quality of the construction industry under the international standards. Importantly, the practical economic benefits are offered to the customers”, as what expected for such solution by The President of NS BlueScope Lysaght Vietnam – Mr. Nguyen Cao Tri.

Moreover, professional technical support services are also provided to optimize the construction solution and efficiency compared with the traditional solution and strictly follow the installation and use instructions.

Comment