Sustainable development in the construction industry is increasingly prioritized by enterprises and investors. This is reflected in the focus on minimizing the impact on the ecosystem and living environment by using fewer materials, increasing construction efficiency, minimizing safety risks in construction, etc. Accordingly, new construction technologies such as composite steel decking are considered one of the solutions to contribute to the industry’s sustainable development.

Composite steel decking is a form of composite structure of concrete and steel decking. In particular, steel decking has a specific wave-shaped structure, helping to minimize the thickness and weight of the floor. The profile does not use formwork boards, and the concrete layer cast in place on the steel decking surface should be thin and light with a positive impact on the frame and foundation of the building.

Currently, the application of composite structures and decking is quite popular around the world in industrial buildings, multi-story factories, commercial buildings, civil buildings, public works, etc.

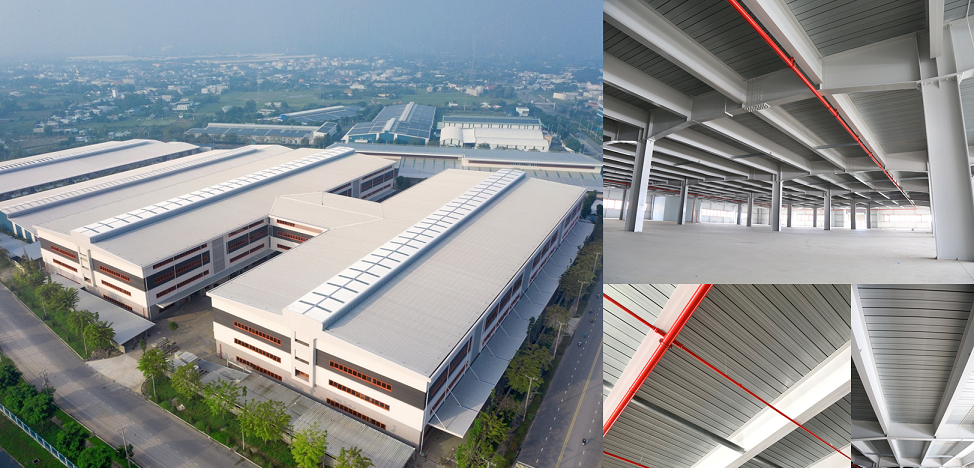

Kizuna – Ready Serviced Space multi-story factory has applied the new-generation Lysaght® Bondek® II composite steel floor solution. Photo: NS BlueScope Lysaght Vietnam

According to Dr. Pham Cao Hung, senior lecturer at the University of Sydney (Australia), steel-concrete composite structures are superior to traditional reinforced concrete structures thanks to their high bearing capacity, long spans, compact and aesthetic components, accelerated construction progress, and labor cost saving. In addition, this solution minimizes construction waste during the construction process because steel components are manufactured at the factory and only transported to the site for assembly, eliminating the need for formwork.

“This is one of the important criteria towards choosing more sustainable structural and construction solutions, promoting the use of renewable materials, and reducing the impact on the environment in the future,” the expert added.

Grasping this trend, combined with the understanding of the Vietnamese construction market, in 2017, NS BlueScope Lysaght launched Lysaght® Bondek® II – one of the advanced steel decking solutions from Australia to replace traditional formwork panels and lower steel layers in construction floor systems. Around the world, many projects implemented this solution such as Marina Bay Sand (Singapore), Singapore Changi Airport, Petronas Twin Tower in Malaysia, and One Shelley Street building (Australia). In Vietnam, Lysaght® Bondek® II is applied in Thaco Truong Hai executive office building in Chu Lai Industrial Park – Quang Nam, Long Beach Resort – Phu Quoc, Kizuna Floor – Long An, Millennium – Quang Ngai, and Landmark 81, the tallest building in Vietnam.

The tallest building in Vietnam, Landmark 81, features Lysaght® Bondek® II. Photo: NS BlueScope Lysaght Vietnam

After multiple improvements, NS BlueScope Lysaght Vietnam’s steel decking saves up to 15% in costs and reduces construction time by up to 20% compared to traditional concrete. According to technical experts of NS BlueScope Lysaght Vietnam, the floor surface is aesthetically finished and durable thanks to advanced steel materials integrated with ActivateTM technology.

Currently, there are many design standards for composite structures, such as the AISC 360-16 for the US market or the Eurocodes 4 in Europe, and the AZ/NZS 2327:2017 standard from Australia.

In Vietnam, NS BlueScope Lysaght selected Eurocodes and Australian design standards. The company also has Megafloor design software specifically developed for Lysaght® Bondek® II with three steps: formwork design for the concrete pouring process, composite steel decking design when the concrete has reached enough strength, and fire resistance design.

Petronas Twin Tower (Malaysia) utilizes the Lysaght® Bondek® II composite steel floor solution. Photo: NS BlueScope Lysaght Vietnam

The quality of the steel decking slab has been confirmed through practical tests according to Australian standards regarding the long spans of the decking slab during concrete pouring, the bond between the decking slab and concrete as a composite system, and the fire resistance of the decking system according to British standard BS476

“The Lysaght® Bondek® II floor system has a minimum fire resistance time of REI 60 minutes and a maximum of REI 240 minutes (according to the BS476 standard). Meanwhile, standard 06-2020 for the floor for Grade I work only requires a maximum fire resistance time of 60 minutes, the technical expert added.

“This solution was also introduced by NS BlueScope Lysaght Vietnam to the construction business community in a mid-August webinar. “We hope that businesses in the industry can access advanced global construction trends and apply them in practice, thereby not only gradually improving the overall quality of the construction sector according to international standards, but more importantly, bringing practical economic benefits to their customers,” said Mr. Nguyen Cao Tri, President of NS BlueScope Lysaght Vietnam.

In addition, NS BlueScope Lysaght also provides professional technical support services to optimize the construction plan, compare effectiveness with traditional methods, and closely monitor the installation and usage process.