Vietnamese people have a huge demand for cars, which is predicted to continue to increase in the coming time as Vietnam is in the beginning phase of motorization. Ford Group has identified Vietnam as one of the four key markets (along with Thailand, South Africa, and Australia) to bolster investments in resources and marketing. To get an overview, we have an interview with RUCHIK SHAH, General Director of Ford Vietnam, about the company’s development strategy.

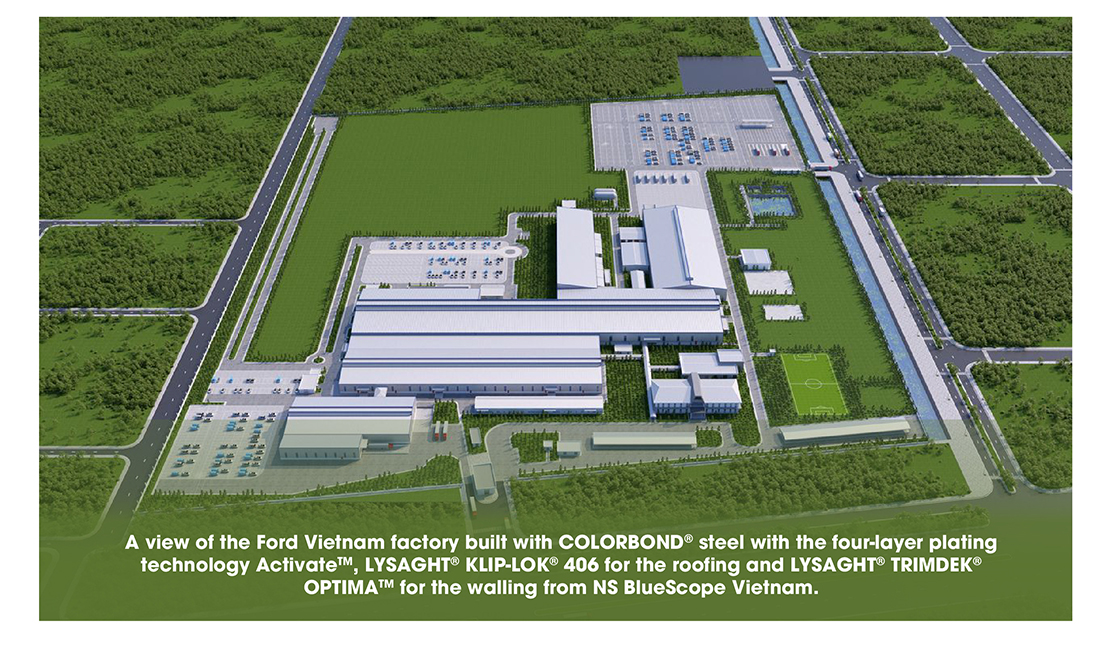

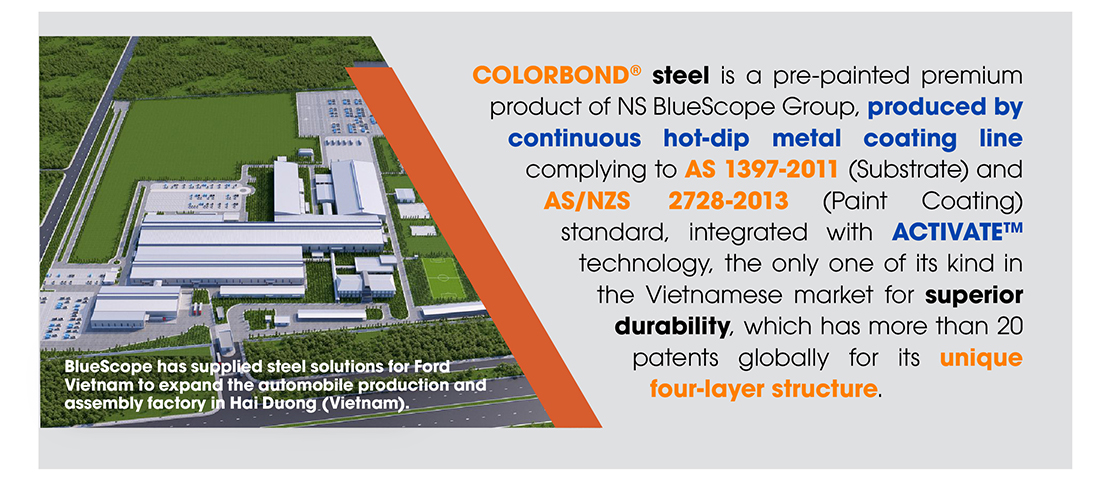

Mr. RUCHIK SHAH: Alongside the market growth, Ford Vietnam has cemented its position on the global map. Vietnam is recognized as one of Ford’s key markets. To consolidate this position, since 2020, Ford Vietnam has announced an additional investment of 82 million USD (over 1.9 trillion VND) to boost the capacity at its automobile factory in Hai Duong from 14,000 vehicles per year to 40,000 units per year.

The investment expansion package was allocated to almost every stage in the factory, including the construction of modern and highly automated car body welding and painting workshops. In addition, the assembly workshop was completed while the logistic and material areas were adjusted and rearranged to improve the efficiency of production and the quality of products assembled at the factory.

Located in Hai Duong City, Hai Duong Province, Ford Vietnam’s factory has operated since 1997. Ford Hai Duong is also one of the first automakers in Vietnam to achieve quality certificates of ISO 9001, ISO 14001, QS 9000, and ISO/TS 16949 – 2002. At the same time, Ford Hai Duong is one of Ford Motor’s key factories in the Asia-Pacific region. The factory always adheres to global manufacturing processes with the highest production quality.

The investment and project would boost the Ford Hai Duong factory’s capacity to 40,000 vehicles per year, raise the total production area to 226,000 square meters (an increase of 60,000 square meters), and attract 500 employees working at the factory. At present, the factory operates two shifts per day with nearly 1,200 direct employees. We assemble Ford Ranger pickup trucks, Ford Transit minivans, and Ford Territory SUVs. These are Ford’s strategic product lines, which have taken the lead or ranked among the best-selling products in their segments for many consecutive years.

As of present, the investment expansion project at the Ford Hai Duong factory has been completed. The production area is equipped with cutting-edge technology and extensive technical improvements for the production lines. Specifically, the car body welding workshop is up to 90% automated with an interlock system to control operation safety, the welding process, and weld quality to ensure error-free operation. The new painting workshop boasts an automatic conveyor system to transport vehicles from input to output, optimizing time and labor.

Ford Vietnam adopts the most modern robots from Germany’s Durr Group. The painting process of each vehicle at the factory is fully automated, ensuring the quality of the paint surface, thickness, and gloss according to Ford Motor’s standards. The dry paint separation technology, through X-dry filters, circulates air for the robot spray booths to save paint, save energy, and protect the environment by filtering all paint dust particles.

Furthermore, the finishing workshop has been upgraded with an automatic conveyor, which can be flipped for two-sided assembly, and Swedish torque wrenches that precisely control torque. The quality inspection area at the Ford Hai Duong factory has been equipped with a steering control system using the most modern 3D simulation technology from Germany. The dynamic steering system, which automatically balances the vehicle with high reliability, ensures the optimum quality of each vehicle when it leaves the factory.

The upgraded assembly line allows the Ford Hai Duong plant to assemble modern and typical vehicles, such as the Ford Ranger, Ford Territory, and Ford Transit, and to be ready for future product lines. Ford is proud to have delivered nearly 300,000 cars of various lines to Vietnamese customers. In particular, to date, the proportion of domestically assembled cars has gained the upper hand, with more than 70% of Ford’s sales in Vietnam, creating many direct and indirect jobs as well as contributing to the local budget.

Absolutely. In the coming time, Ford Vietnam will continue to complete the process and look for opportunities to increase production efficiency. In the field of automobile manufacturing and trading today, it can be seen that brands are making efforts to own modern production lines and apply advanced technology to bring the best products to suit customers’ tastes. Therefore, Ford identifies the customer experience as its unique competitive point.

Accordingly, Ford Vietnam applies the group’s Ford+ strategy with a customer-centric approach. We carry out a series of activities to upgrade the process system, establish dealer standards, and apply technology in both sales and services. Specifically, Ford Vietnam has simultaneously implemented a plan to upgrade dealer standards (Ford Signature) for dealers nationwide. At the same time, we complete the process system to improve the experience for new customers (Ford Guest Experience) according to global standards in order to ensure the synchronization and consistency of customer service quality.

Comment