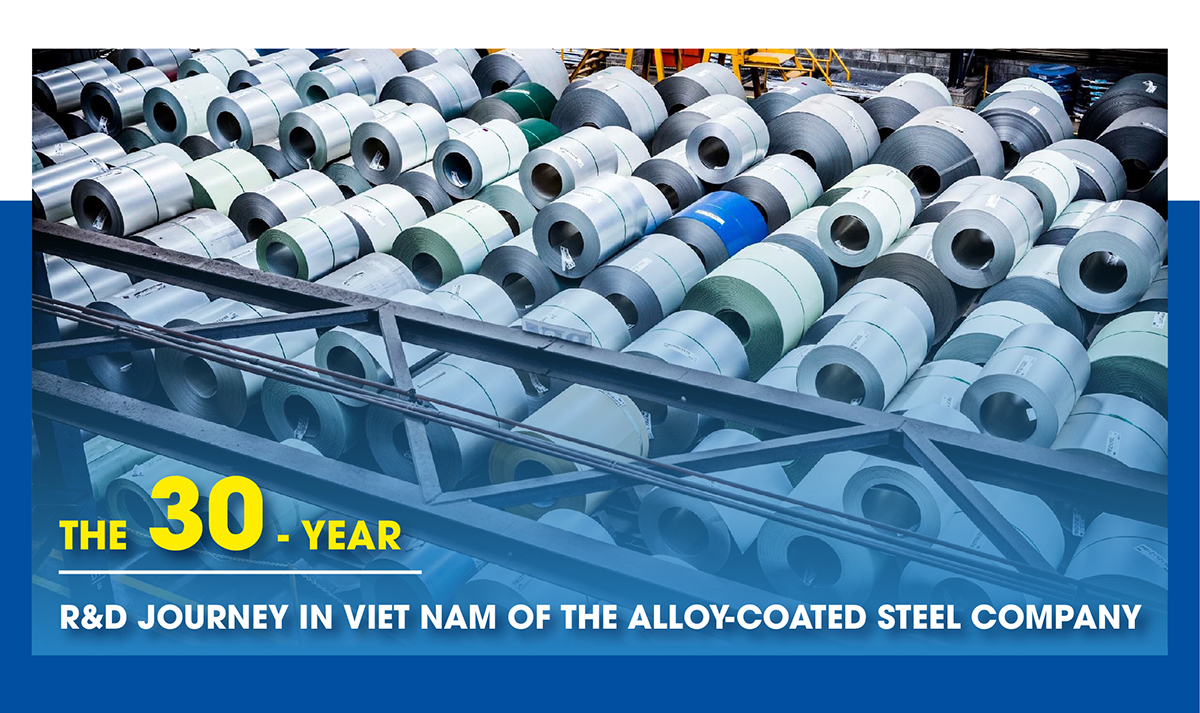

NS BlueScope Vietnam has spent 30 years asserting a presence in the market, with pioneering research and development (R&D) at the forefront of its success. In Vietnam, many large enterprises welcome the wave of opening research centers, as they understand that R&D is necessary aspect of closely adheres to business survival. One of the pioneers of alloy-coated steel industry, NS BlueScope Vietnam, fully embraces this belief. The company’s vice president, Dang Thanh Hung, spoke with VIR’s Thanh Van about the Australia-based brand’s 30 years journey as a leader in alloy-coated steel technology.

EARLY INVESTMENT IN R&D

Mr. Dang Thanh Hung: As a business, we obviously need to weigh and measure opportunities, costs and profits. But with R&D, we need to weigh it in the long term. Customers have higher and higher expectations for quality of products and services and R&D is indispensable to improving quality and is key to increasing competitiveness. So the story of R&D is not about cost anymore, but about “to be or not to be”.

People from Gen X, like me, have experienced this. We witnessed the rise and fall of many giant empires. We are the people who had childhood under red-tiled roofs and large dormitories, and matured with high-rise buildings close together, covered with corrugated iron or other modern materials.

Therefore, in the business and the construction industry in particular, firms are forced to keep pace with the times. If we move slowly, we will be left behind, and then fall into oblivion. R&D is a prerequisite for us to keep pace.

“PIONEER” IN TECHNOLOGY BUILDS ON R&D

Mr. Dang Thanh Hung: When it comes to R&D, we talk about being at the forefront. Therefore, we must develop technology ahead of time and set new industry trends. That’s how BlueScope uses R&D as a competitive edge.

When we first entered the market, Vietnam’s alloy-coated steel mainly used just zinc steel, which is susceptible to corrosion, rust and have short lifespan. BlueScope paved the way to lead the industry to the next level by introducing two-phase, aluminium and zinc-coated technology in 2005.

However, our goal is to provide buildings with the most durability against rust, especially in the polluted and highly corrosive environment, by continuing to innovate. Therefore, in 2019, we once again introduce a breakthrough with our four-phase, alloy-coated technology, exclusive to BlueScope.

With the growing wave of industrial plants in Vietnam, we are delighted that investors are increasingly taking a long-term perspective on choosing sustainable materials. If you look across the three regions of the country, it is not difficult to name large projects using our four-phase alloy-coated steel, such as the Long Son oil refinery and the Goertek electronics factory in Bac Ninh.

We started conducting R&D more than 20 years ago, with a total investment of more than $68 million. Tens of thousands of profile panels have undergone Q-Fog cyclic testing and salt spray testing in laboratories and outdoor tested in different exposure sites in Australia and around the world.

Additionally, test huts and building applications have been tested in the real-world conditions and in severe marine environment to verify the technology’s quality.

The four-phase alloy-coated technology was born in this context and overcame the disadvantages of two-phase coated technology. We apply four-phase technology to all alloy-coated steel product lines, including Inok® technology for the residential segment and Activate™ technology for the industrial segment.

It is our long-term vision and the determination to consistently innovate that remain unwavered against all market changes and is the keys to help us stay firm in our strategy.

Even with the current trend of green construction, we are at the forefront as well. We launched technologies to support LEED certified investors. Typically, our Thermatech® technology helps to reduce the absorption of heat from the Sun, thereby reducing the surface temperature of alloy-coated steel.

We are the first and only alloy-coated steel manufacturer in Vietnam to be granted Green Label certificate by the Singapore Green Building Council for all product lines in the residential and project segments. We are looking forward to winning the global ResponsibleSteel™ certificate for a responsible and sustainable alloy-coated steel producer by the end of this year – on the occasion of our 30th anniversary in Vietnam.

Comment