More than 20 years have passed since the first day of its establishment in Hung Yen. 4P has grown from a small factory with 50 employees to a large company with hundreds of employees. 4P is one of the Vietnamese suppliers in partnership with several major brands in the global electronics industry, like LG, Canon, and General Electric.

4P has a relatively more favorable start than the average, given that Tri used to hold the position of Deputy Director of LG Electronics for a decade. Therefore, Tri has insights into the demand and strict requirements of product quality that LG is scouting for its suppliers.

Seeing this opportunity, Mr. Tri decided to invest to establish 4P in 2001 when Vietnam received the third wave of FDI with a strong influx of capital from foreign investors into the manufacturing industries such as textiles and garments, footwear, and others. The founder of 4P shared his investment philosophy of getting the best bang for every buck you invest. To put it more clearly, don’t chase quantity, but focus on quality. The assembly industry is not as simple as people think, using only hands to join existing parts.

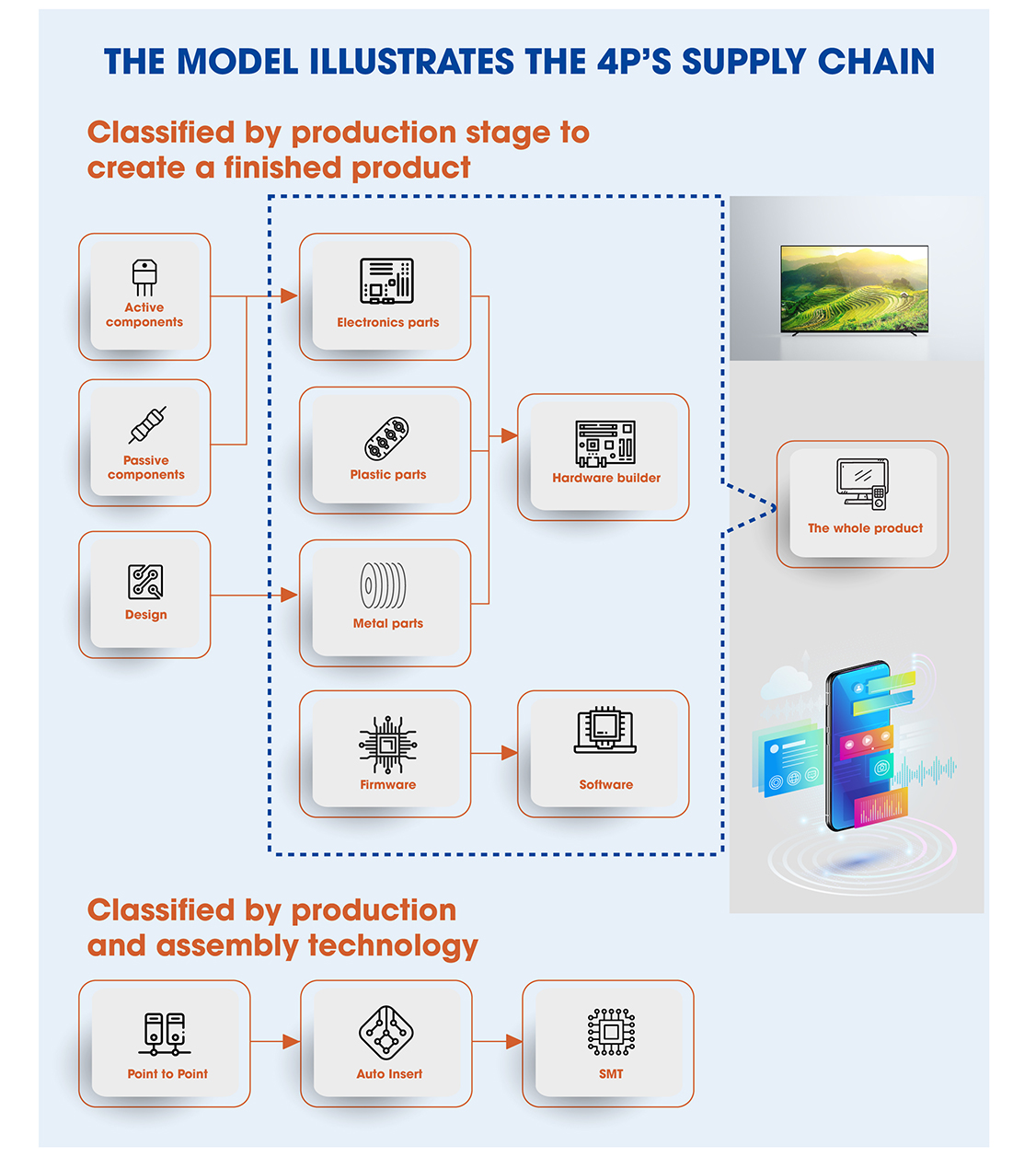

Based on his understanding of the strict requirements of large customers, Mr. Tri intends that 4P only focuses on investment in certain production stages and technologies as a foundation to start participating in the supply chain. When the third wave of FDI capital began in Vietnam, it was risky to opt for investment to serve the high-tech products. However, after two decades, 4P’s achievements are a testament to their wise choice.

After identifying the production stage for investment, 4P has set a number of goals to achieve: Manufacturing, assembling high-tech products, promoting the application of high technology, constantly innovating, etc. At Hai Phong-based Trang Due industrial park, where LG’s electronics complex is situated, 4P is the only Vietnamese company with deep engagement in the production chain, which is one of the important links of this complex.

At an event themed “Welcoming the wave of supply chain shifts in the electronics industry,” co-organized by NS BlueScope Vietnam and Saigon Times, Mr. Tri shared about the closed loop model comprising five factors: Standardization, good quality, competitive price, on-time delivery, and a good service guarantee. They are the five crucial pillars behind the success of 4P. It is also a formula for Vietnamese businesses to refer to and take a step further into the very competitive supply chain.

For a deeper analysis, the first factor, Standardization, can be divided into three pillars: human management, product quality, and the production process. Regarding standards, it is impossible not to mention the information technology system behind them, such as ISO, 5S, or 6 Sixgma, which are the tools to support managers in improving the company’s management capacity, followed by the step of controlling costs and product quality well.

After having a standard system, it is time to focus on improving product quality by implementing smart management systems and making constant investments in technology. The following two factors, namely competitive prices and the supplier’s reputation, are the top concerns of buyers, underpinned by ensuring on-time delivery. Finally, when you have built customers’ trust in good products, competitive prices, and a skilled team, it is time for the customer care team to step in. Maintaining close relationships and connections while ensuring good service will be the final piece of the puzzle to bring Vietnamese suppliers to the supplier list of large electronics corporations.

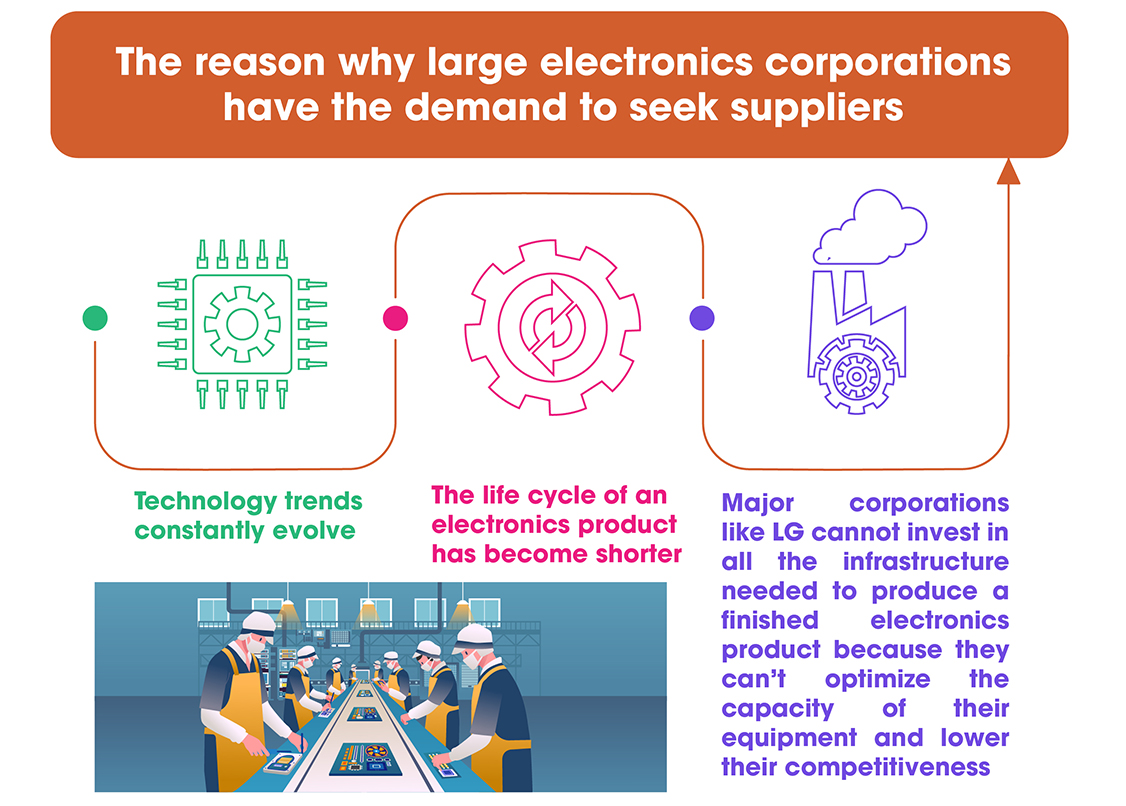

Mr. Tuan Anh said Vietnam’s electronics companies mainly participated in the assembly stage in the supply chain. It means the capacity of domestic electronics producers has yet to meet the rising demand in the market. One of the reasons is that electronic product life spans are relatively short and often need feature and design updates. However, not all domestic businesses have enough resources to make investment in new product research and brand development activities.

From the perspective of foreign companies, Lieu Van Han, chairman of the Taiwan Electronics Industry Association in Vietnam, proposed that the Vietnamese government issue support policies that are more suitable and tailored to each business. Because every company has different needs, they need different policies.

As an investor who closely follows reality, 4P’s founder, Hoang Minh Tri, shares his view that businesses should make their own efforts before relying on state policies. Despite the numerous policies issued by the government to facilitate the operation and development of businesses, policies often lag behind practice. In addition, it is difficult to resolve problems arising in ministries, branches, and localities overnight. The most important thing businesses should clearly understand is determining their goals and expected implementation stages, thereby paying the costs to train human resources and build a quality management system to improve competitiveness.

Comment