All new technology has its own story that goes hand in hand with research and development, yet taking more than two decades for R&D like BlueScope’s

Activate™ technology is barely seen in the industry. Surprisingly, the

‘abnormality’ in the ActivateTM R&D enables this unique technology to set a ‘new norm’ in Viet Nam’s alloy-coated steel industry. The story of researching and

developing Activate™ told by Mr. Daniel Parker, Process Development Manager, BlueScope Innovation unveils underlying know-how of this very technology.

At BlueScope, we understand that our success depends on our

customers choosing us. That’s why we work closely with them to create value and trust, share ideas and bring the benefits of

innovative, sustainable products and services to their own

businesses and projects.

We have manufacturing operations in 18 countries, and sales offices in other locations around the world. Through this supply network,

around 14,000 BlueScope people serve thousands of customers worldwide. That’s to say we have an in-depth understanding of customers’ needs and our customers, as end users, have always been looking for ways to expand the lifespan of their plant/workshops/buildings, maximizing their investment. This is where our Activate™ technology fits in.

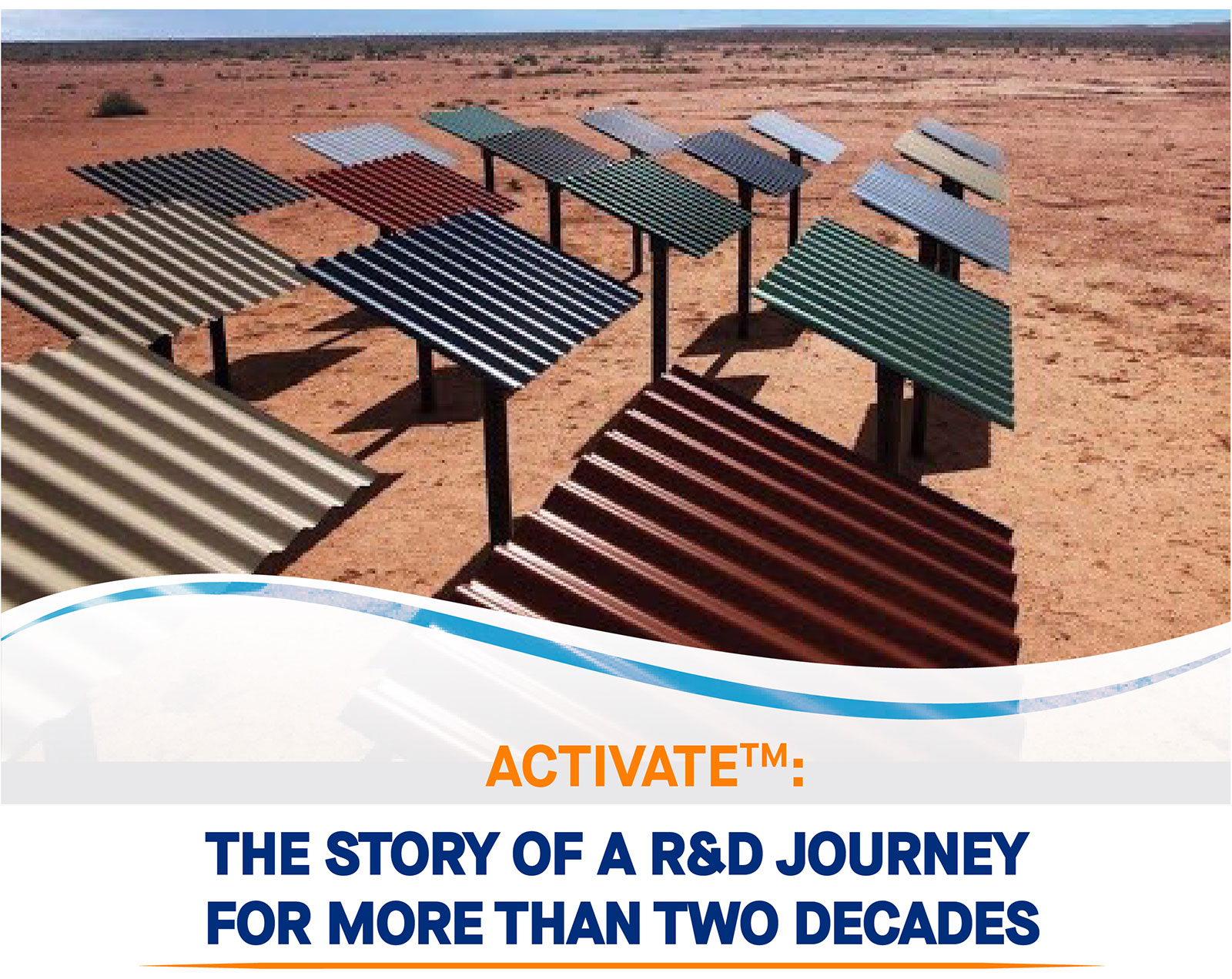

In order to ensure the new generation of COLORBOND® steel and ZINCALUME® steel with ActivateTM coating technology lives up to the highest expectations in durability, we conducted a comprehensive testing

program that included accelerated

laboratory corrosion tests, as well as real-world outdoor exposure tests. Over 20 years, more than 8,000 profile panels have undergone Q-Fog cyclic testing and salt spray testing in laboratories. A further 10,000 panels have been tested in 22

different exposure sites in Australia and around the world. The Activate technology is covered by over 20 patent applications that have been filed worldwide, related to the unique and effective microstructure in our new technology that differentiates it from any other product on the market.

Additionally, during the product

development stage, 50 building sites comprising a wide range of applications, as well as five

purpose-built test structures, have been tested in real-world

conditions and severe marine

environment. The new technology has also been validated by 3rd party testing and benchmarked against the latest coated products around the world through the French Corrosion Institute, proving that COLORBOND® steel with

Activate™ technology is highly

durable, especially at the cut edge, and more resilient to scratches and scuffs during construction.

The key factor behind BlueScope’s patented Activate™ technology lies in the unique composition and microstructure of 4 phases including Aluminium – Zinc and two strategically positioned magnesium compounds.

With the unique composition and microstructure of the 4 phases, our new

generation COLORBOND® steel and ZINCALUME® steel create a self-sealing effect that greatly improves corrosion resistance at cut edges, screws holes, and

scratches. This mechanism improves the protection of projects in difficult

environments such as marine and polluted industrial sites, enabling them to

withstand the test of time. Obviously, it’s a good “candidate” for any projects in Viet Nam from benign environments to more challenging environments close to marine or industrial areas.

Our Activate™ technology was launched in Australia in 2013. After six years of

presence in a variety of global projects, NS BlueScope Vietnam made a business decision to introduce this very technology to Viet Nam’s market as a breakthrough to improve our product quality, thereby accelerate the growth of the country’s

construction industry.

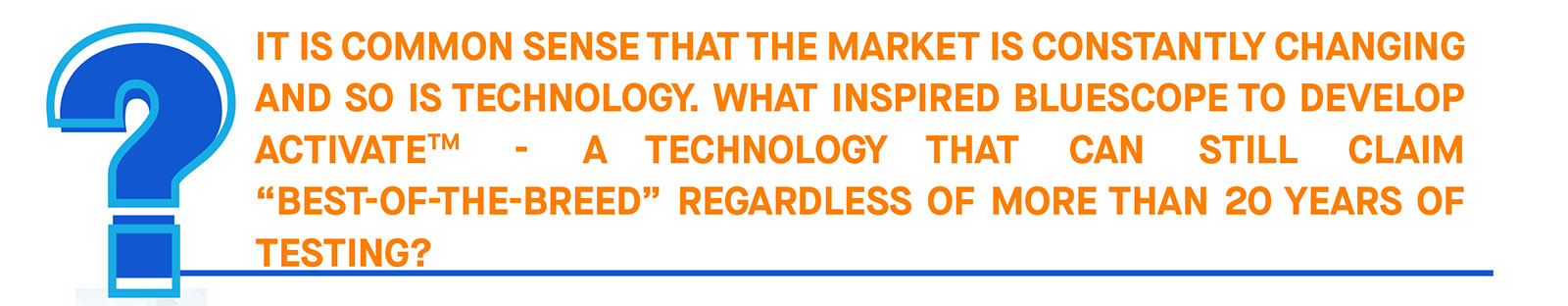

As our ActivateTM technology sets a new standard in Viet Nam’s alloy-coated steel industry, it is welcome by prestigious investors across several sectors. We are now having big world-class factories such as Vinfast, Kizuna, FM Logistic, C.P., Masan applying our new coating technology in Colorbond® steel or Zincalume® steel. We believe they will be the trendsetters in the industry with our solutions.

Comment