The electronics industry is a key industry in the national economy, holds a key position, and has a strong spillover impact on other industries. At the same time, the industry is also a measure of the level of economic and technical development in every country worldwide. Many major electronics companies around the world have invested in building high-tech electronics production facilities in Vietnam, such as Samsung, LG, Foxconn, Fukang Technology, and LG Display. However, these production companies also face the problem of electronic waste. What should be done to promote sustainable, environmentally friendly development?

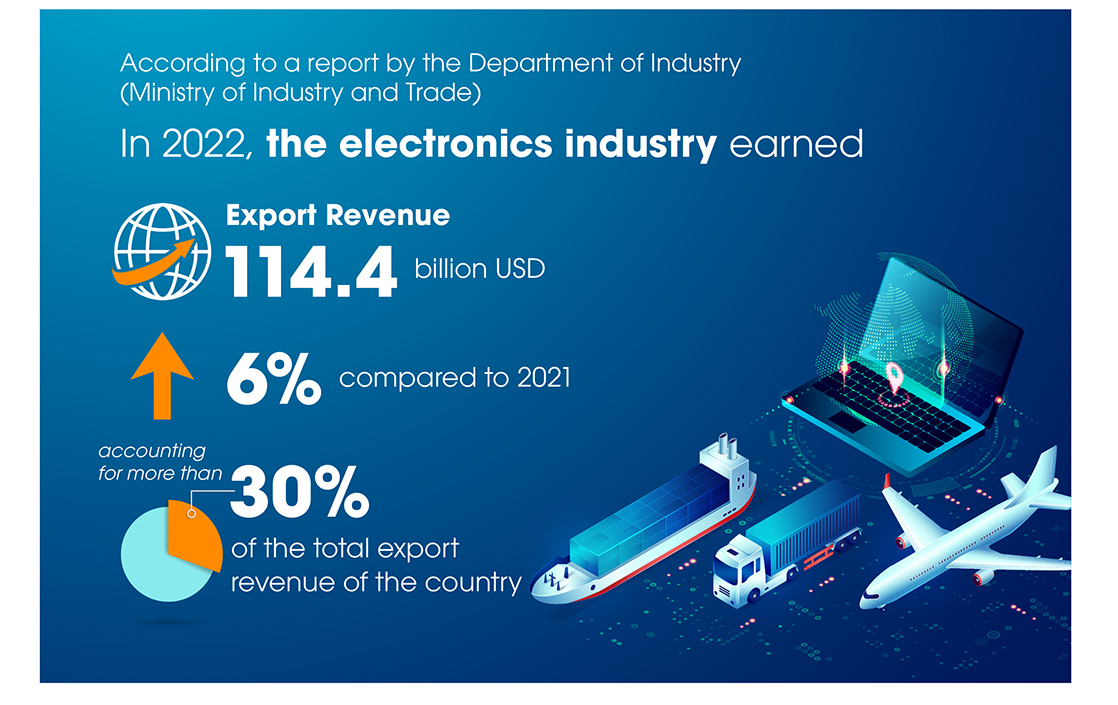

Despite the impact of the pandemic over the past three years, Vietnam’s electronics industry still maintains its growth rate and import and export turnover.

The development of the electronics industry has attracted large investors from multinational corporations in Korea, Japan, and China in the field of manufacturing electronics components.

However, experts said that the potential of the electronics industry also comes with challenges.

Electronic waste contains many different components, mainly metal and high molecular-weight compounds, such as old, broken household appliances, microchips and electronics boards from old electrical and electronics devices, old tech accessories, and other used or damaged electrical and electronics appliances and equipment, causing environmental pollution and affecting human health.

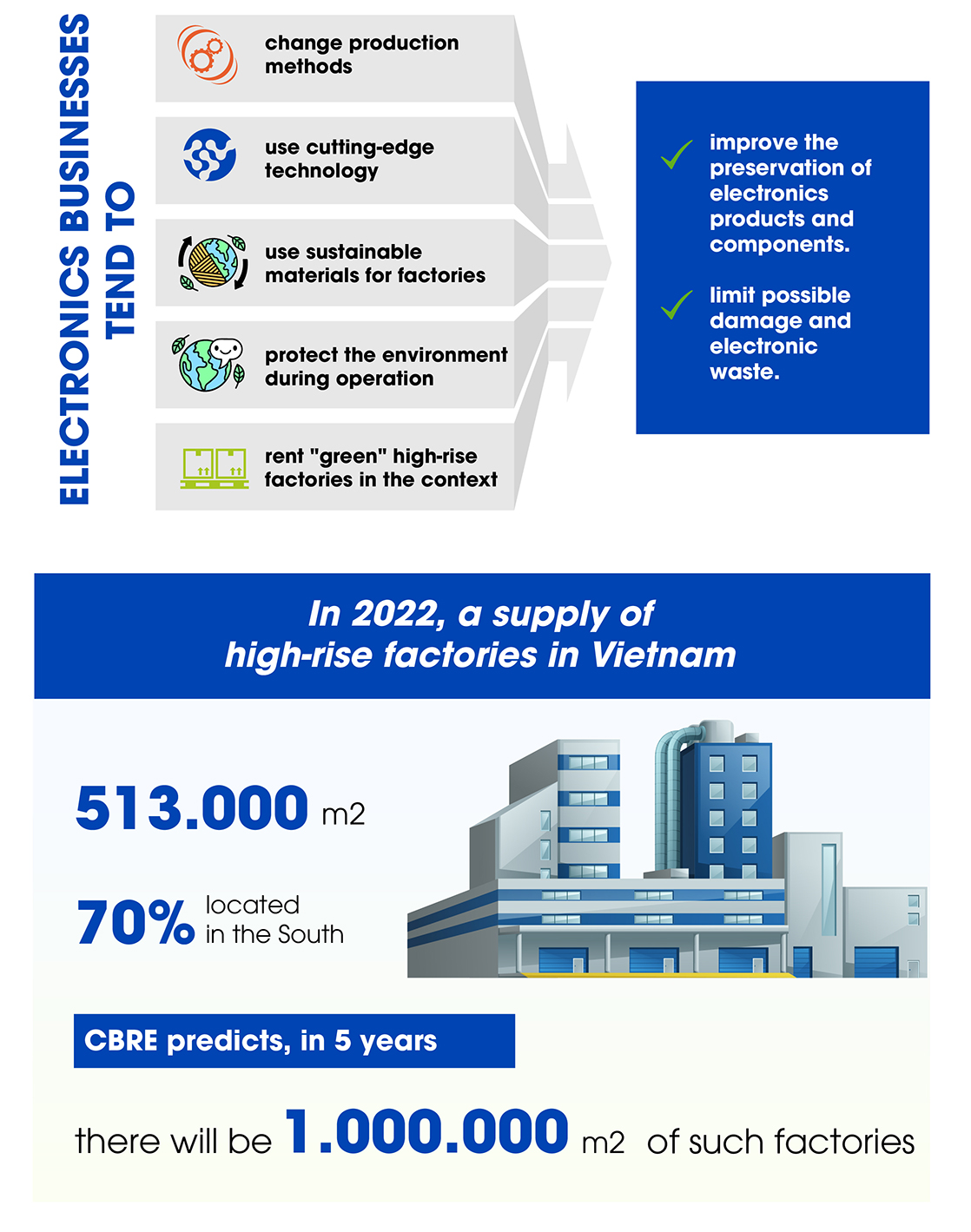

Besides these challenges, electronics businesses are gradually changing their production methods, using cutting-edge technology and sustainable materials to protect the environment during operation. In addition, businesses have a high demand for renting “green” high-rise factories in the context that the land reserve for building factories and warehouses is increasingly scarce.

This model has become more common across many projects under construction in major cities and provinces, such as Ho Chi Minh City, Dong Nai, Binh Duong, Long An, Hai Duong, and Bac Ninh.

However, renting “green” factories is a short-term solution. More local companies have recognized and considered applying advanced technology themselves to invest in facilities, build factories to attract customers, reduce product costs, and take advantage of available resources. NS BlueScope Vietnam’s brand has become one of the construction material sources for “green” factories selected by many companies. The company has more than 130 years of experience in Australia.

Based on the study of investors’ pain points during the factory construction process and extensive experience in the steel industry, BlueScope has developed COLORBOND® for Panel steel solution for clean rooms and architectural walls, which meets all the strict requirements about durability, electrostatic discharge protection (with the clean room solution), aesthetics, insulation layer adhesion, and others. Therefore, the company, along with sandwich panel manufacturers, can produce high-quality products that satisfy investors’ demands.

Comment