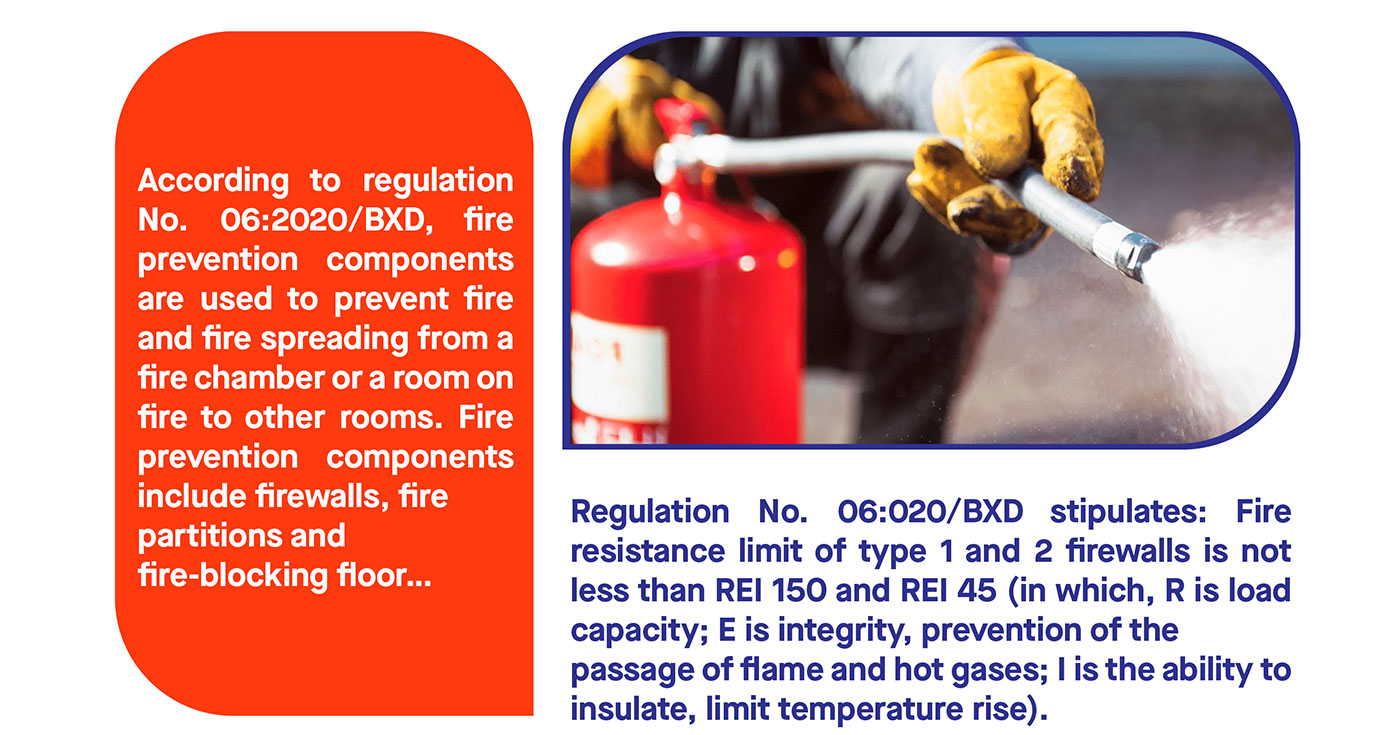

On July 28th 2020, Regulation QCVN No. 06:2020/BXD on Fire Safety of Buildings and Constructions took effect. This means such construction entities as

consultants, contractors, investors… are to put a second thought upon choosing building materials including covering panels and partitions in order to meet the requirements of QCVN No. 06:2020/BXD?

However, as regulated by QCVN No. 06:2020/BXD, organizations and individuals involved in construction investment, management and usage of houses and buildings are to more strictly comply with fire protection and prevention

standards to improve safety.

In contrast, the previous regulation specified that the fire resistance limit of type 2 firewall was not less than REI 60. This means that the fire resistance limit of type 2 firewall specified in QCVN 06:2020/BXD is lower, easier to meet than QCVN 06:2010/BXD.

QCVN 06:2020/BXD also stipulates fire resistance limit of type 1 and 2 fire partition, not less than EI 45 and EI 15; Fire resistance levels of type 1, 2, 3 and 4 fire-blocking floor, not less than REI 150, REI 60, REI 45 and REI 15, respectively. These fire resistance limits are kept unchanged as compared to QCVN 06:2010/BXD.

QCVN No. 06:2020/BXD also adjusts the fire resistance limit of some other fire prevention components such as doors and fire valves… to be stricter than that of QCVN No. 06:2010/BXD.

Finally, soundproof and heatproof panel used as a non-load bearing wall for normal constructions with class 4 fire resistance only need to meet E15 standard according to QCVN No. 06:2020/BXD.

With the aforementioned regulations, is QCVN 06:2020/BXD going to “make it difficult” for materials suppliers, including manufacturers of the new

generation wall and partition systems, such as sandwich panel?

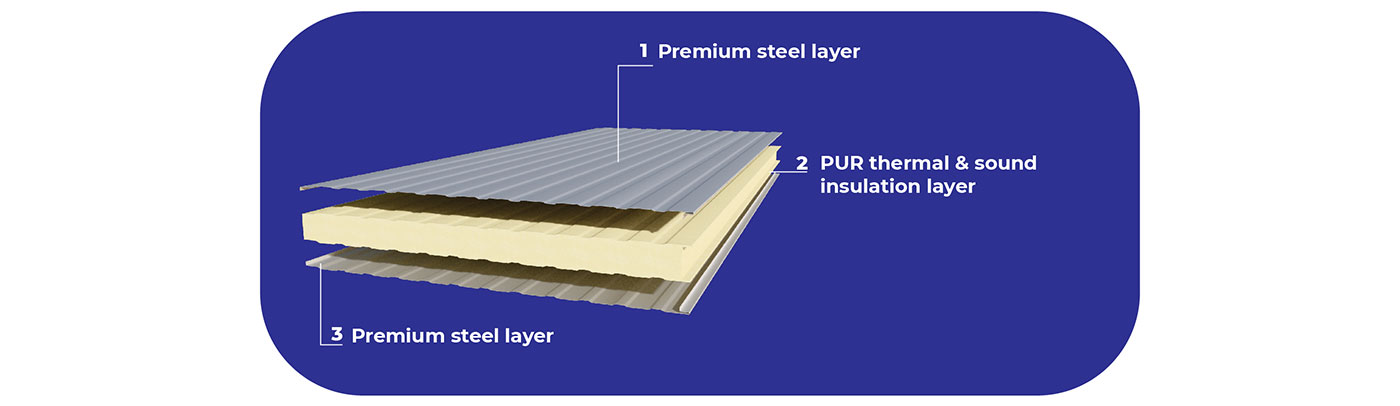

Sandwich panel is an insulating PUR panel, consisting of 3 layers, in which layer 1 and layer 3 are high-grade galvanized steel, layer 2 in the middle is soundproof and heat-insulating.

With outstanding features such as excellent sound and heat insulation, high durability, noise resistance, fast construction, efficient energy use, etc.,

sandwich panel is the optimal solution to replace traditional brick walls as material for ceilings, coverings and partitions in constructions while meeting the requirements for durability and aesthetics.

The thing is whether the material supplier is to apply for testing to see if it meets the regulations of QCVN 06:2020/BXD whenever this kind of material is used.

Fortunately, Decree No.136/2020/ND-CP detailing a number of articles and

measures to implement the Law on Fire Prevention and Fighting and the Law Amending and Supplementing a Number of Articles of the Law on Fire Prevention and Fighting, issued by the Government on November 24th 2020 has troubleshot for materials suppliers.

That is, Decree No. 136/2020/ND-CP specifies structural samples that must be tested; allows the socialization of inspection and especially batch testing.

That means, when a product is certified by a competent authority that its

production batch has been tested for fire resistance, it does not need to be tested again, and automatically qualified for usage in construction. Therefore,

constructions entities do not need to concern about the complicated and costly testing anymore.

Moreover, as for Sandwich panel, the materials used in panel production are all heat-resistant materials with outstanding durability.

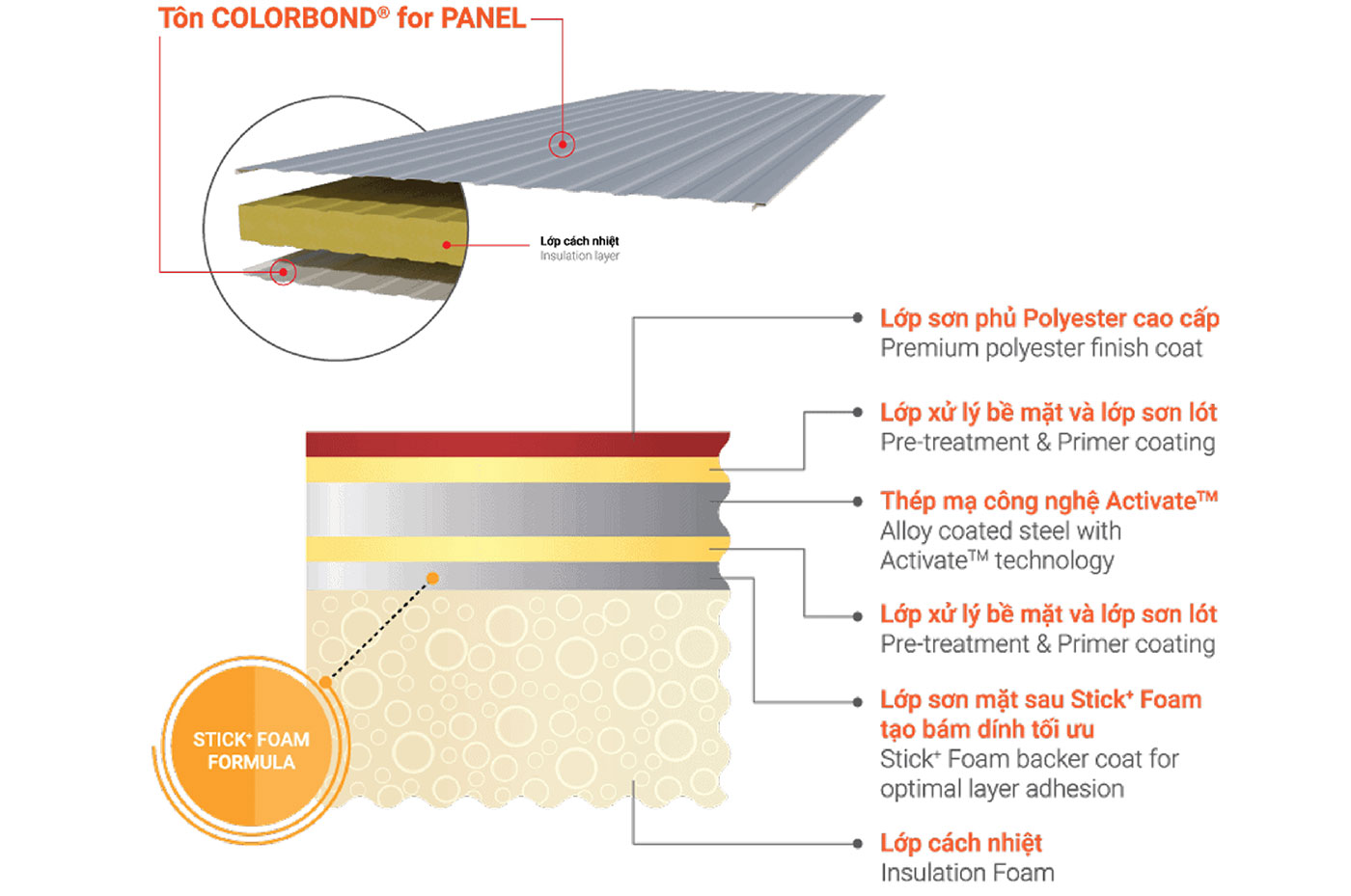

COLORBOND® is a typical sheet material for sandwich panel provided by NS

BlueScope Vietnam – an Australia-based enterprise specializing in galvanized steel. This is also the very material that meets the covering requirements for

constructions as regulated by QCVN No. N06:2020/BXD.

In addition, this material is integrated with advanced technologies such as: Stick + foam to enhance optimum adhesion of the steel substrate layer to the insulation surface; durable polyester paint system, resistant to fading and peeling; and especially Activate ™ technology, known for its four-phased matrix protection for the steel substrate, completely different from the traditional Al-Zn alloy coating, providing superior corrosion resistance, even in severe environments (marine and polluted industrial sites). COLORBOND® For Panel thereby contributes to the

durability, aesthetics, and adhesion to ensure effective heat and sound insulation as well as fire resistance for the finished panel product.

According to NS Bluecope Vietnam, the mandatory compliance with QCVN 06:2020/BXD is not a difficulty for construction entities. What manufacturers are expected to do is to constantly improve techniques to produce products that meet the specified standards as well as stringent needs of the market.

In addition, project consultants as well as consultants of the materials supplier also need to understand and define the plant class, fire resistance threshold of each project, mandatory regulations on fire safety for each area and fire prevention structures as regulated. This will enable them to choose the

correct materials for the building. In so doing, the project will not only meet the requirements of fire prevention and fire-fighting but also ensure investment

efficiency, reduce unnecessary costs during investing and building process.

Comment